Description

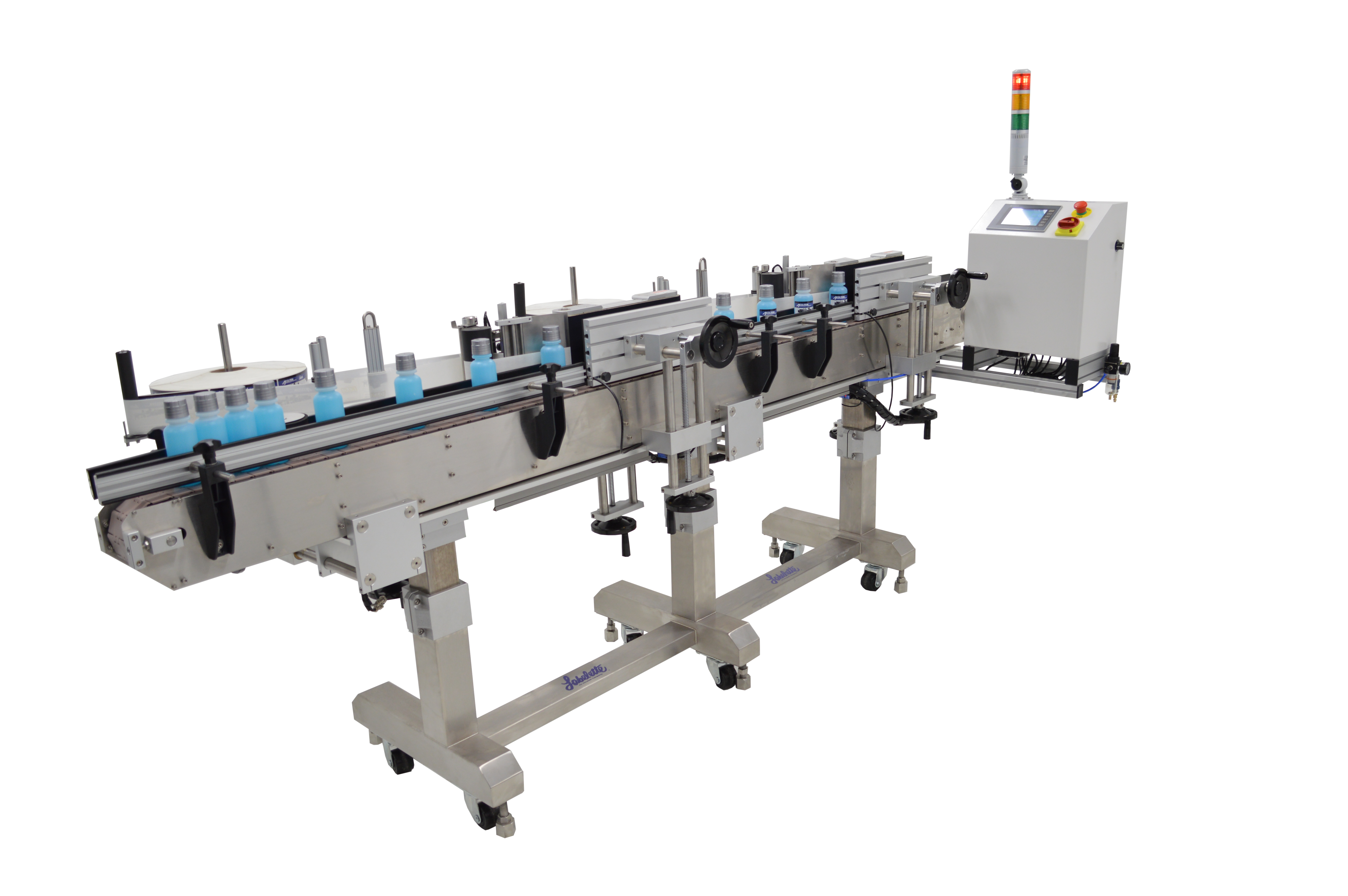

The APS-206 is economical, self-contained and easy to operate. This automatic labeling system comes equipped with a 10 ft. variable speed conveyor. Additional features include, stepper motor driven label dispenser, take up reel and label tampers. The easy to use design makes it simple to change bottle and label sizes. APS-206 can handle up to 6” tall labels. The APS-206 switches to the second label head when the first label head runs out of labels. Labels can be loaded on the first label head without stopping the machine.

The speed, versatility, and reliability of the APS-206 is exceeds competing labelers, at a fraction of the price. Our versatile labelers apply labels to plastic, metal, fiber, and glass containers. The APS-206 handles a variety of container shapes.

Features

-

- Two label heads

- Auto Label Learn™ (Automatic label setup)

- Label heads dispense up to 6” (15.2 cm) tall labels

- Touch screen control system with job memory

- Heavy duty construction for 3 shift operations

- Sanitary stainless steel frame

- Easy to operate hand wheels for quick setup

- Conveyor with eight different speed selections

- Label dispensing tracks conveyor speed changes with optical container sensing.

- Height adjustable

Options

-

- Hot stamp coder for date or lot printing,

- Alpha numeric starter kit hot stamp coder

- Tiltable peel plates for labeling conical bottles

- Clear label sensor

- Casters

Specs

| Height: | 53” |

| Length: | 79” |

| Depth: | 45” |

| Weight: | ~575 lbs. (260 kg) |

| Labeling Speed: | Up to 175 CPM |

| Electrical: | 110 VAC – 10APMS, 56/60 Hz (220VAC Optional) |

| Label Size: | Length: 0.5” – 22” (1.25 cm – 55 cm) |

| Label Size: | Height: 0.75” – 7.75” (2 cm – 14.5 cm) |

| Labeling Direction: | Left side off – Outside peel |

| Components: | Tamp Station and Synchronized Top Hold Down Belt |