Description

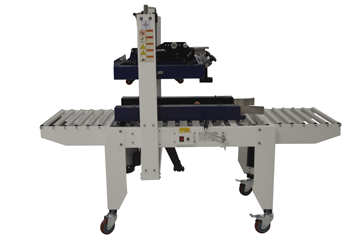

In the packaging industry, taping boxes closed prior to shipping is not a difficult problem, but it is slow and tedious work. Taping boxes closed while minimizing wasted tape would be easier and faster if there was a way to automate the task. Accutek is the leading innovator in the packaging industry, and that is why we are proud to offer our clients a case taping system.

Gripper Belt – Conveyor System

The case taper has powered gripper belts that pull the box between top and bottom mounted 2” tape head dispensers. The tape applying mechanism automatically cuts the tape and tamps it in place.

Our Accutek sales engineers know the packaging industry, and we are proud to offer our clients a wide variety of packaging equipment. In addition, we offer everything you need to fill, cap, and label your products. Our equipment is manufactured to the strictest quality standards in sanitary conditions that ensure we deliver the best possible packaging equipment to our valued customers. Call for a quote, no matter your packaging challenges.

Features

-

- Left and right drive belts.

- 2” top and bottom tape applicators.

- Tape overlap length can be adjusted from 5mm to 50mm.

- Roller working table.

- Blade guards.

- Crank Handle adjustments for carton width and height.

- Leg height adjustment 240mm.

- Includes Roller Infeed and Exit Conveyors and Casters for portability.

Options

-

- 3inch Tape Head

Specs

| Machine size: | 1830×840×1330mm, (72×33×52inches) |

| Machine Weight: | 160kg, (353lbs) |

| Maximum Case Size: | 600mm Wide x 600mm Tall |

| Minimum Case Size:: | 120mm (4.72”) Wide x 150mm Tall |

| Power Requirements: | 110 VAC – 15 Amp |