Description

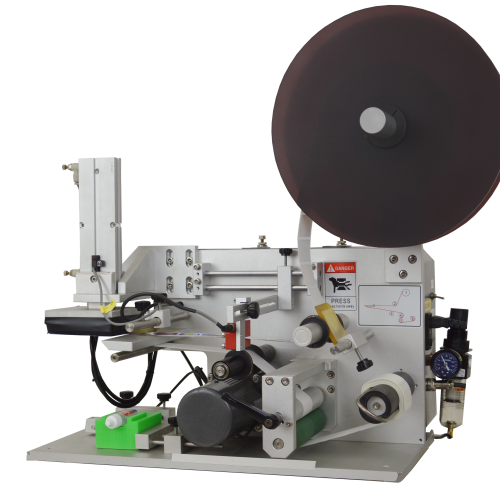

The Labelette SG Labeler will separate the label from a stack, feed the label, transfer adhesive, and accurately apply the paper label to the container. Designed for spot, face, 3/4 full wrap-around applications on cylindrical containers. Simply insert unlabeled container and remove labeled product. Skip glue adjustment can save up to 90% of adhesive cost.

Recommended products for this machine

The Labelette SG Labeler will separate the label from a stack, feed the label, transfer adhesive, and accurately apply the paper label to the container.

Features

-

-

- Machine is Ready to Use in only 10 minutes

- Digital Thermostat for longer adhesive life in glue pan.

- 360 degree rotary glue seals to keep the glue in the pan

- Overhead pressure arm for proper adhesion

- 2×2 welded tubing frame for increased durability

- Label feed now uses rotary metal sensing promity

- Fully adjustable adhesive skip with Digital Input

- Programmable glue length

- Simplified label feed system using a stepper motor instead of a clutch

- Job Memory

- 15 minutes warm up time

-

Options

-

- Labelette Glue for Perfect Labeling

- Hot Glue Option

- Cold Glue Option

- Stackable Container Guide

- Overhead Pressure Arm for Proper Label Adhesion

- Synchronized Registration for Containers with Molded Handles or Lugs

- 7-day timer (For Automatic Warmup)

- Casters, two are self-locking

- Thermal Transfer Label Printer

- Aerosol Label Solve, for easy spray on wipe off clean up

Specs

| Label Length: | 3 |

| Label Height: | 1.75 |

| Electrical Requirements: | 120VAC – 16 AMPS (220 Optional) |

| model: | Labelette-SG |

| height: | 55 |

| length: | 25 |

| width: | 36 |

| weight: | 200 lbs. (90.71 kg) |

| speed: | Up to 50 CPM* |

| minimum paper thickness: | 0.0035 |