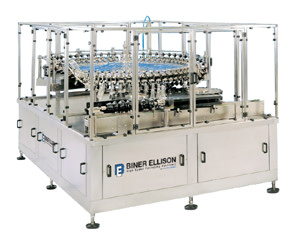

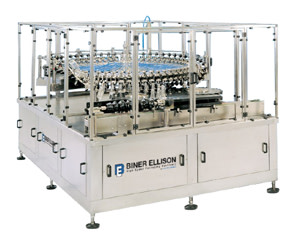

Description

Accutek’s Inversion Sterilizing Conveyor is a crucial system for sanitation of inner bottle and cap surfaces when filling hot beverages. The sterilizing conveyor automatically inverts containers 90° in order to utilize the products high temperature to disinfect the bottle mouth and cap without any additional heat source. Containers are then automatically returned to an upright positions for cooling and further packaging. Universal cleat design accommodates a wide range of container dimensions and shapes.

Features

-

- Stainless steel construction

- No squeeze on bottle, eliminates distortion

- Variable sterilizing control time

- Universal cleat design

- Wash down construction

Options

-

- Custom shaped / size cleats

- Extended lengths

Specs