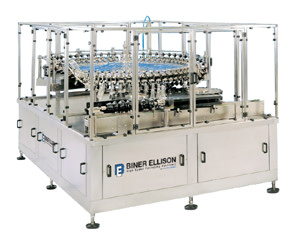

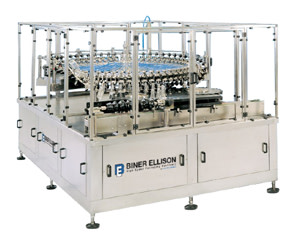

Description

Rotary bottle rinsers are an ideal companion to any high speed filling line. The R-Rinser utilizes a variable amount of water or cleaning solutions to provide a thorough cleaning and draining of the containers. The rotary rinser with its self contained liquid system, multiple cycle capable, and the “no bottle-no rinse” feature, provides a fast and efficient environment for bottle rinsing. We offer customized solution treatment options, including multiple rinse cycles and ionized air rinse. The Biner Ellison rotary R-Rinser is available in three frame sizes and includes one rinse cycle, 10’ conveyor shell, color touch screen controls, air diaphragm and one set of tooling.

Recommended products for this machine

Jugs, plasitic bottles, food containers, metal containers, almost every type of bottle or jar

Features

-

- New boxed tube sanitary stainless steel frame for added strength and durability

- Safety interlocks on all removable safety guarding

- Touch screen control package includes job memory, tooling memory and management lockout

- Self contained recirculating liquid system

- Fast change over with minimal tooling

- Tool less change parts

Options

-

- Upgrade to multi cycle rinse

- Electronic Integration to filler

- High temperature upgrade

Specs

| Max Fill Size: | 61 oz. |

| Electrical Requirements: | 220/240 VAC, 20 AMP, 3 Phase |

| Air Requirements: | 220/240 VAC, 20 AMP, 3 Phase |

| height: | 72 |

| length: | 54 |

| width: | 61 |

| weight: | apx. 1800 lbs. (816 kg) |

| speed: | 160 CPM |