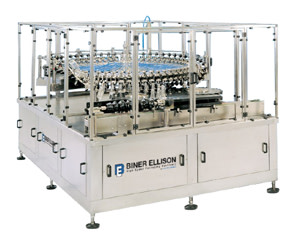

Description

Rotary bottle rinsers are an ideal companion to any high speed filling line. The R-Rinser utilizes a variable amount of water or cleaning solutions to provide a thorough cleaning and draining of the containers. The rotary rinser with its self contained liquid system, multiple cycle capable, and the “no bottle-no rinse” feature, provides a fast and efficient environment for bottle rinsing. We offer customized solution treatment options, including multiple rinse cycles and ionized air rinse. The Biner Ellison rotary R-Rinser is available in three frame sizes and includes one rinse cycle, 10’ conveyor shell, color touch screen controls, air diaphragm and one set of tooling.

Features

-

- New boxed tube sanitary stainless steel frame for added strength and durability

- Safety interlocks on all removable safety guarding

- Touch screen control package includes job memory, tooling memory and management lockout

- Self contained recirculating liquid system

- Fast change over with minimal tooling

- Tool less change parts

Options

-

- Upgrade to multi cycle rinse

- Electronic Integration to filler

- High temperature upgrade

Specs

| Max Fill Size: | 64 oz |

| Electrical Requirements: | 220/240 VAC, 20 AMP, 3 Phase |

| Air Requirements: | 220/240 VAC, 20 AMP, 3 Phase |

| height: | Height: 72 |

| length: | Width: 92 |

| width: | Length: 86 |

| weight: | 3500 lbs. (1587.5 kg) |

| speed: | 480 CPM |