Description

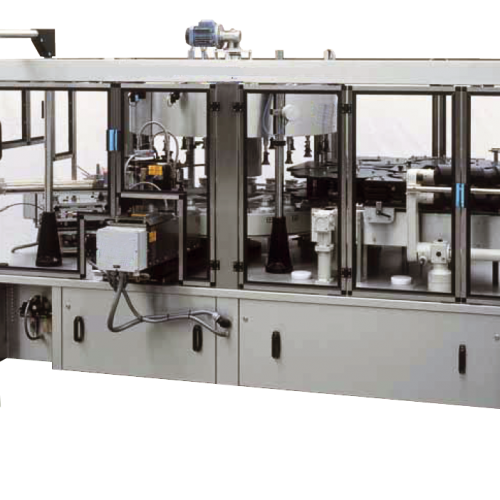

The Rotary Overflow Filler is a fast and accurate production system that can be used for all free-flowing and non-carbonated liquids including foods, beverages, cosmetics, chemicals, and much more. The ROF Fillers use fill to level technology to deliver product to the container. The ROF Series includes more standard features, safety systems, and new production technology which boost its productivity past any machine in its class.

Rotary Overflow Fillers allow customers to produce visually appealing and consistent fill levels regardless of volume irregularities and container shapes, which can be caused through the bottle molding and forming process. The ROF machines compensate for these minor changes and variations in the container volume allowing for a uniform and appealing fill level. These machines can accommodate all types of containers comprised of rigid plastic, metal, and glass from ounces to gallons.

Features

-

- Touch screen control package

- Electronic variable speed controls

- Accommodates glass, plastic, and metal containers up to 600 CPM

Options

-

- Specialty pumps available

- Explosion Proof option

- Teflon Seals and hoses

- Sanitary Conveyor System

Specs

| Fill Size: | 1 oz – 1.3 Gal (30mL – 5L) |

| Viscosity Range: | 1-2000 cp |

| Foamy Product: | Yes |

| Corrosive Product: | Yes |

| Heated Product: | Yes |

| Particulates: | No |

| Electrical Requirements: | 220/240 VAC, 20 AMP, 3 Phase |

| Air Requirements: | 100psi @ 5 u0096 10 CFM |

| model: | ROF-64 |

| height: | 89″ |

| length: | 86″ |

| width: | 92″ |

| weight: | 5200 lbs. (2358.68 kg) |

| speed: | 600 CPM |