Description

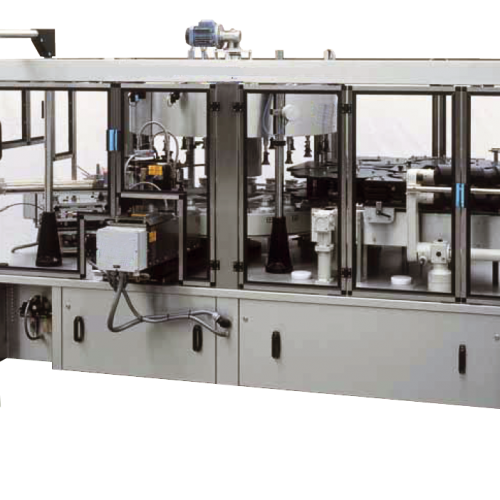

The RVF-40 Rotary Volumetric Filling Machine is a high-speed rotary filling system. This machine is perfectly engineered to position the power transmission for the main turret infeed and outfeed star wheel and timing screw on top of the machine. This system is designed to keep the important components away from the wetted area, which helps to deliver a precise variable speed control, longevity, and high.

This machine is able to handle all container shapes and sizes and can easily deliver filling accuracies up to +/- 0.5%. This versatile system is available with 6 to 20 fill stations depending on your filling requirements and goals.

Features

-

- Suitable for filling a wide range of liquids from light oils to heavy viscous semi-solids at speeds of up to 450+ CPM

- Touch screen control packaging includes job memory, tooling memory, and management lockout

- Variable speed “Top Drive” system keeps key systems away from wetted areas for easy access and lasting performance

- Can accommodate glass, plastic, and metal containers

- Synchronized “pump to turret” design for smooth filling of light or thick products at a high rate of production

- Each machine incorporates safety interlocks, polycarbonate guarding, and other integrated safety features

- All systems include self-aligning tool less change parts for quick and trouble-free changeover

- Easy operation and maintenance

Options

-

- Diving Heads

- Explosion Proof

- Sanitary Conveyor System

Specs

| Length: | 54” |

| height: | 89” |

| width: | 61” |

| weight: | ~2200 lbs. (1000 kg) |

| Electrical Requirements: | 220/240 VAC, 20 AMP, 3 Phase |

| Air Requirements: | 87 PSI @ 2CFM |

| Filling Speed: | Up to 240 CPM1 |

| Viscosity Range: | 1-18,000 cp |

| Foamy Product: | Not Recommended |

| Corrosive Product: | YES |

| Heated Product: | YES |

| Particulates Product: | YES |