Description

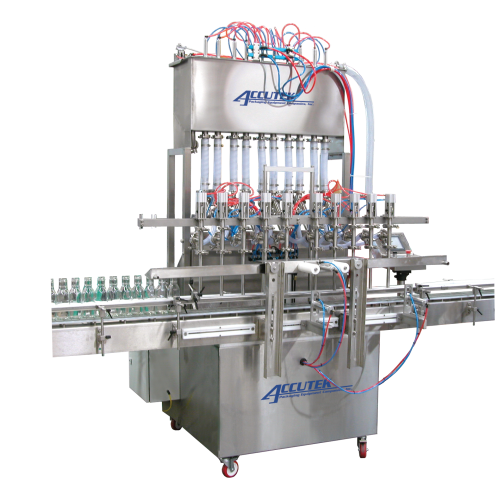

Auto indexing adds a new dimension to the Mini-Pinch, a filling machine best suited for filling aqueous solutions, thin and light oils. The Automatic Indexing Mini Pinch is a six-head, timed flow volumetric filler that has a fill rate of up to six ounces per second. Depending on pump options, indexing reduces the operator work load and adds a robust job memory feature with a state of the art touch screen. The operator can fill a tray of bottles with a single button push. The machine fills a row of six bottles and automatically moves to the next row fills and repeats for up to twenty rows. The Automatic Indexing Mini Pinch is able to fill containers between 5mL – 475mL.

Accutek Automatic Indexing Mini Pinch filling machines come complete with adjustable tabletop stand, automatically indexed fill wand, individual flow control adjusters, six stainless steel fill nozzles, silicone and vinyl food grade tubing, pinch valve system, an easy to operate microprocessor, and a pump.

Recommended products for this machine

Any aqueous free flowing liquid including: Water, fruit juices & extracts, liquid tea, liquid coffee, food coloring, vegetable oil, milk, tomato juice, some light salad dressings, perfumes, essential oils, ink, thin liquid soap, shampoo’s, light makeup remover, motor oil, urethane, silicone, urine, alcohol, and much more.

Features

-

- Direct from drum draw kit

- Sanitary contact parts and fluid path available

- Six stainless steel filling heads with individual flow controls

- Toolless removal of sanitary stainless steel manifold

- Easy to operate using a touch screen controller with job memory

- Simple to use fill wand auto triggered by PLC.

- Includes adjustable tabletop stand

- Positive displacement pump

Options

-

- Thin nozzles (For products that string or drip)

- Long nozzles (For bottom up filling to reduce foam)

- Heat or corrosive product packages (Contact parts and tubing)

- Sanitary stainless steel hoppers

- Stand alone frame with or without casters

- Custom bottle guides and trays

- Custom sized, shape, or material nozzle upgrades

- Pumps/tanks

Specs

| Height: | 48 |

| Wide: | 31 |

| Length: | 30 |

| Fill Size: | 5mL – 475mL |

| Viscosity Range: | Under 1 cP to 1000 cP (centipoise) |

| Air Requirements: | 80 psi, 1 CFM- |

| Electrical requirements: | 110VAC/5 AMPS optional: 220 VAC |